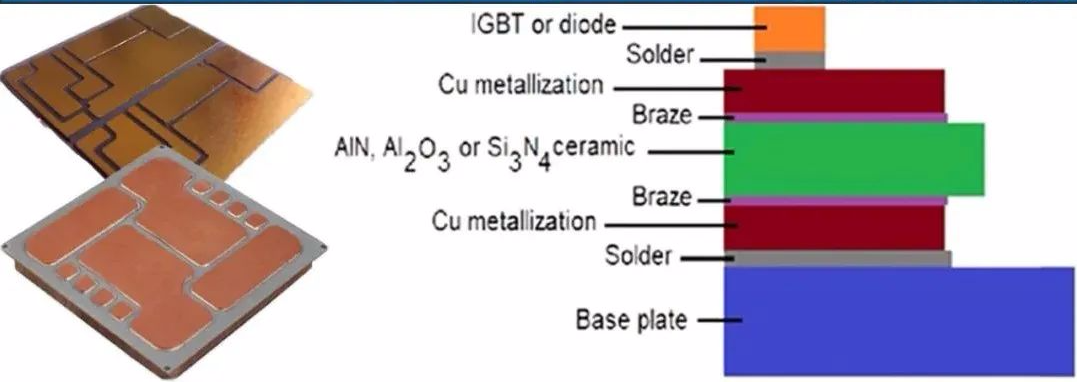

AMB(Active Metal Brazing Substrate) is the further development of DBC technology. It is a method to use a small amount of active elements such as Ti and Zr contained in the filler metal to react with ceramics to form a reaction layer that can be wetted by liquid solder, so as to realize the bonding between ceramics and metals. AMB is combined by chemical reaction between ceramic and active metal solder at high temperature, so its bonding strength is higher and its reliability is better.

1.Material:Aluminum Nitride/Alumina/ZTA/Si3N4.

2.Function:Insulation and heat dissipation ceramics.

3.Type:Metallized ceramic.

4.Can be customed:yes,please provide drawings for specific products.

AMB ceramic substrate for Power Modules

Product Description:

AMB ceramic substrates have higher bonding strength and cold and thermal cycling characteristics and have made progress in applications such as high-power semiconductor modules, high-frequency switches, wind power generation, new energy vehicles, power locomotives, and aerospace.

Our Service:

Please contact us for customization. We can also supply Aluminum Nitride (AlN) Ceramic with thermal conductivity up to 230W/mK

Specification:

| Copper/Ceramic/Copper specification(mm) | ||||

| AlN-AMB | 0.30/0.38/0.30 | 0.30/0.64/0.30 | ||

| Si3N4-AMB | 0.25/0.32/0.25 | 0.30/0.32/0.30 | 0.80/0.32/0.80 | 1.20/0.32/1.20 |

| ZTA-AMB | 0.30/0.32/0.30 | 0.40/0.32/0.40 | ||

Company Advantage:

Huaqing Founded in 2004, with sum investment of 80Million RMB, registered capital 40Million RMB. Huaqing's AlN & Al2O3 ceramic products have high thermal-conductivity, low dielectric constant, good dissipation factor and excellent mechanical property compared with the other factories in the industry. AlN & Al2O3 ceramic are widely used in HBLED, opto-communication, IGBT, power devices, TEC and the other high-end applications.

Workshop & Equipment:

Packaging & Delivery:

Deliver by UPS,DHL,Fedex etc

Why you need our services, you know you're getting highly qualified professionals who have the expertise and experience to make sure your project is done properly and functions.

if you would like a free consultation, please start bg completing the form: